- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

- Chinese: Business Department 0539-8782638

- English: chau@dengzhuochem.com

Methane/ Natural Gas Steam Reforming Catalyst

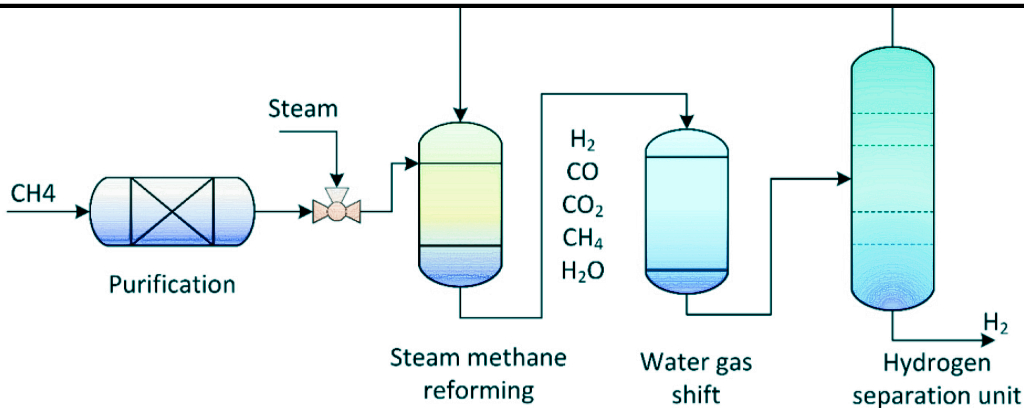

Steam reforming of natural gas is an important method for hydrogen production in industry, which is effective, economical and widely used in hydrogen plants.

The natural gas/methane steam-reforming catalyst has more reasonable outer appearance structure to improve

strength and outer surface area, more reasonable micro pore structure to improve the effective utilization of

inner surface area. Adding rare earth as promoter to advance catalyst activity at low temperature and anti-carbon formation ability.

PRODUCT DESCRIPTION

The reforming catalyst’s sponge micro pore structure can make it better tenacity so that it is of better heat-expansion & cold-shrink resistance. The 6-

holed shape ensures symmetrical stress patterns and no easy fracture-line.

Based on our experience, we are able to guarantee that increase of pressure drop due to catalyst attrition or breakage will be less than 10% over guarantee period.

The reaction normally takes places at outer surface of the catalyst, therefore a uniform nickel coating has to be insured. The catalyst features an optimized Ni-

content, specially adapted to its surface roughness and porosity. Simultaneously, domed shape allows full utilization of surface.

The reforming catalyst adds rare earth to improve catalyst‘s comprehensive performance.

Adding rare earth canincrease catalyst‘s adsorption capacity to water and also improve its activity at low temperature.

Thus this will allow steam/carbon ratio of as low as 2.0 without risk of carbon formation.

In the unlikely event of a plant up-set which does result in carbon formation, the catalyst can be easily steamed due to large hole sizes, and usually activity can be completely recovered.

The reforming catalyst contains stable aluminum aluminate support, and it can resist nickel and alumina into nickel aluminium spinel.

So it can give additional operational security in case of frequent start-up and shut-down conditions (repeating oxidation and reduction process).

Long mechanism life and good carbon and sulphur resistance can extend catalyst service life.

Name | Reforming Catalyst | |

Model | DZC-S169 /DZC-S1614 | |

Other names | Steam Methane Reforming (SMR) Catalyst | |

Appearance | 6-hole arc honeycomb | 6-hole arc honeycomb |

Size(mm) | Φ16×9×3.5 | Φ16×14×3.5 |

Bulk density (kg/l) | 0.9±0.1 | 0.9±0.1 |

Crushing strength/(N/CM) | ≥300 | ≥350 |

NiO % | ≥14.0 | ≥14.0 |

SiO₂ % | ≤0.2 | ≤0.2 |

Burning weight loss % | ≤5 | ≤5 |

Related products

Cuo Zno Al2O3 Methanol Steam Reforming Catalyst DZC-Z1

Methane/ Natural Gas Steam Reforming Catalyst

FCC catalyst

Synthesis Gas Purification Catalyst DZC-JWH185

<< Previous Page

Next Page >>